Factory Direct Sales 25kg Bag Flour Dust

Basic Info.

| Model NO. | GF-800 |

| Movement Mode | Other |

| Usage | Mine, Gravel Field, Metallurgy, Building Materials, Chemical Industry, Ore-dressing, Colliery |

| Appearance | Open-Type |

| Max Feeding (mm) | as Per Model |

| Capacity(t/h) | 400-600 |

| Motor Power(kw) | 2*(0.18~0.25)Kw |

| Installation Slope | 0 |

| Chute size(mm) | as Per Model |

| Overall Dimension | as Per Model |

| Wind Pressure | 1200-1600 |

| Fan Speed | 2900 |

| Video Outgoing-Inspection | Provide |

| Machinery Test Report | Provide |

| Screen Structure | Woven Mesh |

| Function | Unloading and Screening |

| Running Speed | 1460 |

| Advantage | Avoid The Material Dust Flying Everywhere |

| Product Name | Dust-Free Feeding Station |

| Transport Package | Wooden Box |

| Specification | Stainless Steel |

| Trademark | Gaofu |

| Origin | Henan, China |

| Production Capacity | 10000set/Year |

Packaging & Delivery

Package Size 100.00cm * 80.00cm * 180.00cm Package Gross Weight 600.000kgProduct Description

Product Description

Dust-free feeding station

When the small bag material needs to be unpackedand poured into the next process,it only needs to beunpacked by hand and put into the system.The materiadust generated during the feeding is collected by the dustcollector fan.The material can be intercepted by vibratingscreen (safety sieve),so as to ensure the granule to enterthe next process.

Product advantages1.Easy to clean, hygienic standard design.

2.The feeding platform is in a negative pressure state, no dust leakage, no dust and environmental protection, no loss of materials during the feeding process, and a clean environment is protected.

3.The feeding process is safe to operate, reduces labor intensity, and protects personnel in safe production.

4.It can be connected with positive pressure/negative pressure conveying to feed the production line.

Application field

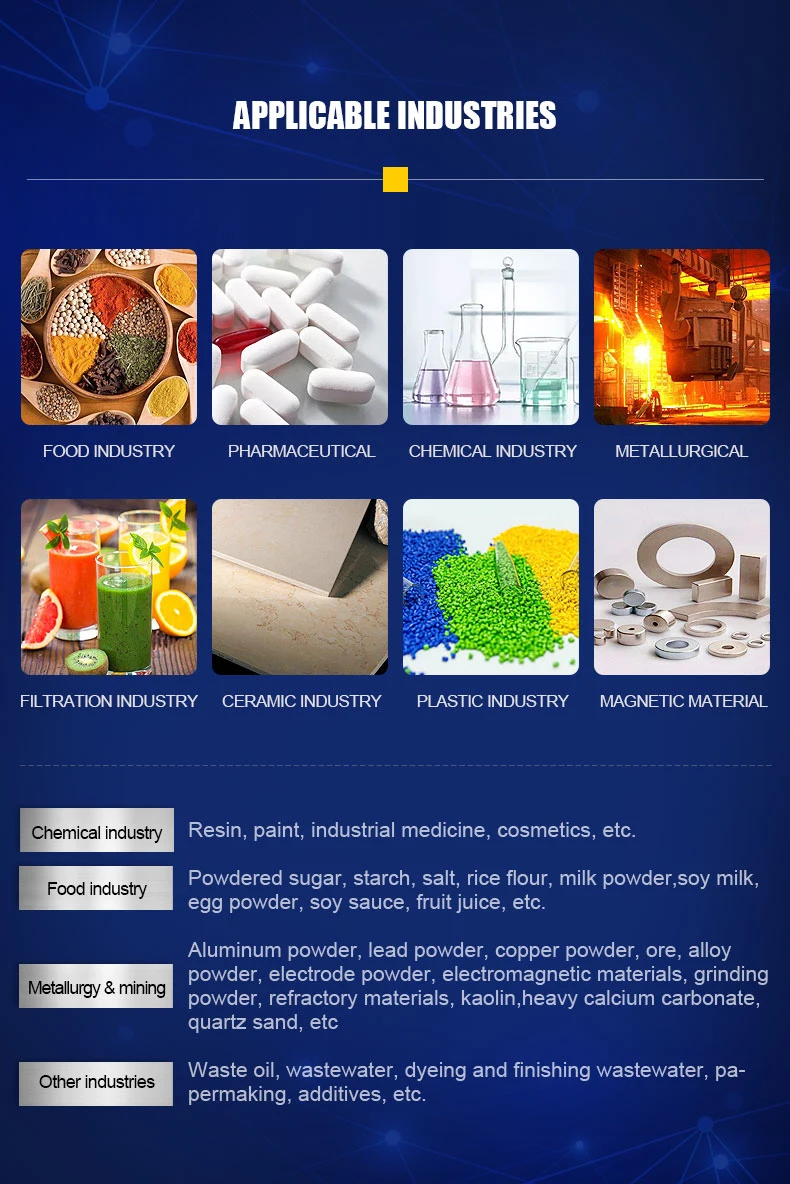

This equipment is suitable for unpacking, feeding, screening and unloading of small bags of materials in the food, pharmaceutical, chemical, and metallurgical industries, especially for manual feeding and pre-screening of powder materials. Due to the function of the dust collection fan when unpacking, it can Avoid material dust flying everywhere.

Application range

Unpacking, feeding, screening and unloading of small bags of materials in food, pharmaceutical, chemical and metallurgical industries

Applicable materials

Suitable for all kinds of powder materials.

Product Parameters

Product Description

When the small bag of material needs to be unpacked and poured into the next process, it only needs to be manually unpacked and put into the system. The material dust generated during feeding is collected by the dust collection fan. When the material passes through the vibrating screen (safety screen), the bulk material and foreign matter can be intercepted, so as to ensure that the finished product (qualified material) that meets the requirements enters the next process.

| Model | GF-800 | GF-1000 | |

| Screen Surface | Layer | 1 | 1 |

| Sieving Area | 0.42 | 0.64 | |

| Screen Structure | woven mesh | woven mesh | |

| Motor | Power(kW) | 2×0.18 | 2×0.25 |

| Speed(r.p.m) | 1460 | 1460 | |

| Force(kN) | 2.5×2 | 5×2 | |

| Amplitude(mm) | 3~4 | 3~5 | |

| Fan | Speed(r.p.m) | 2900 | 2900 |

| Flow(m³/h) | 1550~997 | 1550~997 | |

| Wind Pressure(Pa) | 1217~1641 | 1217~1641 | |

Packaging & Shipping

Recommended Featured

Certifications

Company Profile

FAQ

1. who are we?

We are based in Henan, China, start from 2000,sell to Southeast Asia(40.00%),Domestic Market(27.00%),South America(10.00%),Eastern Europe(8.00%),Oceania(3.00%),North America(2.00%),Western Europe(2.00%),Africa(2.00%),South Asia(1.00%),Eastern Asia(1.00%),Southern Europe(1.00%),Central America(1.00%),Northern Europe(1.00%),Mid East(1.00%). There are total about 301-500 people in our office.2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Vibrating Screen Equipment, Crusher, Conveying Equipment, Mixer, Food Feeding And Screening System

4. why should you buy from us not from other suppliers?

Gaofu company founded in 1982, 20 years screening experience, the company covers an area of 50800 square meters.we posses the independent management right of importing and exporting, our products are spread all over the country, sold in faraway market area

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Contact Us

Tell me the following questions, Then I can send you accurate quotation soon, including additional discount!

Your email addressand telephone will not be shared or published!The proper selection of the vibrating screen depends on the material, mesh size,output required, method of input,abrasiveness of the material etc: 1. Screening product : _____2. Moisture:_____%3. Capacity:________kg/ hour4. Screen layer:_______5. Screen mesh size:______ mesh . ______ mesh. ______ mesh6. Voltage:______V,Frequency:______HZ, 3 phase7. SS304/316L stainless steel or Q235A carbon steel?