Category

Factory Price Model Series 3D Blender Mixer for Pharmaceutical Dry Powder

Factory Price Model Series 3D Blender Mixer for Pharmaceutical Dry Powder INTRODUCTION: The PerMix PTU series Turbula Sh

Basic Info.

| Model NO. | PTU |

| Layout Type | Verticle |

| Mixing Drum Shape | Drum |

| Additional Capabilities | Drying |

| Operating type | Cycle Operating |

| Condition | New |

| Frequency | 50Hz or 60Hz |

| Speed Regulation | Single Speed; Variable Speed |

| Polishing | Dull Polishing; Mirror Polishing |

| Power Supply | 220V/3pH; 380V/3pH; 415V/3pH, etc |

| Construction Material | SS304; SS316L; Carbon Steel |

| Transport Package | Wooden Case |

| Specification | CE |

| Trademark | PerMix |

| Origin | China |

| HS Code | 8474390000 |

| Production Capacity | 100 PCS/Year |

Product Description

Factory Price Model Series 3D Blender Mixer for Pharmaceutical Dry PowderINTRODUCTION:

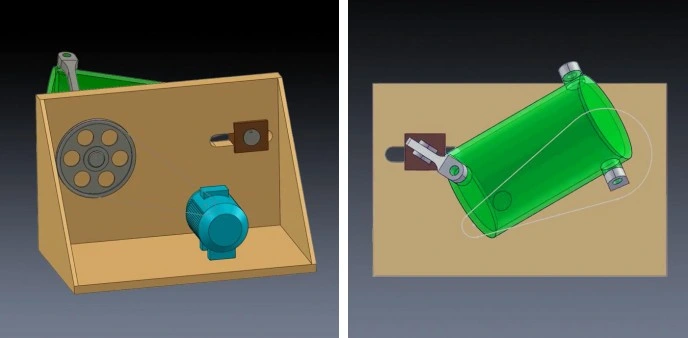

The PerMix PTU series Turbula Shaker Mixer is used for homogeneous mixing of powdery substances with different specific weights and particle sizes. Producing dry-to-wet and wet-to-wet mixtures is also possible. The production process is hygienic and dust-free because the product is mixed in independent containers of variable sizes.

During the mixing process the powder moves on a random direction from center to the end of the trough and on the same time from top to the bottom. In such a multi-dimensional way, the PerMix PTU series Turbula Shaker Mixer needs only short mixing time and relatively low power consumption. The mixer's "Gentle" mixing action is good for final products that are sensitive to high shear of the mixer and tend to break or to reduce their particles size, or are highly abrasive.

CONSTRUCTION MATERIAL & FINISH:

We are able to offer our PTU Turbula Shaker Mixer with contact part to be built in SS304, SS316/316L, Titanium, Duplex stainless steel, Hastelloy, etc. Standard of internal and external finish can be adapted to the customer's needs.

ADVANTAGES:

1. Excellent homogeneity of the mixture due to interaction of rotation, translation and inversion as per the geometric theory according to Schatz special design of the mixing trough, with no dead points, allows a complete discharge of the mixing tank with min. Mixed material residue and easy cleaning.

2. Easy to convert the machine for vacuum loading for better GMP results

3. Sizes from 100 to 1000 lit. Total volume.

4. On small models of Turbula Shaker Mixers, mixing is carried out in independent containers, therefore no contamination and emissions, no extra cleaning.

5. Time-saving, fast exchange of the container, due to simple and fast mounting of the container

| Model | Total Volume, Liter | Operation Volume, Liter | Power, kW | Speed of Mixing Can, rpm | Length, mm | Width, mm | Height, mm | Weight, kg |

| PTU-5 | 5 | 4 | 0.25 | 28 | 600 | 1000 | 900 | 150 |

| PTU-15 | 15 | 12 | 0.37 | 20 | 700 | 1000 | 1000 | 200 |

| PTU-50 | 50 | 40 | 1.5 | 15 | 1120 | 1330 | 1220 | 500 |

| PTU-100 | 100 | 80 | 2.2 | 12 | 1370 | 1550 | 1430 | 700 |

| PTU-300 | 300 | 240 | 4 | 8 | 2000 | 2400 | 2100 | 1600 |

2. Bigger sizes up to 1,000L are available against request.

3. PerMix reserves the right to modify the design without notice.

FAQ:

Q: What is your price level compared with European suppliers and local Chinese suppliers?A: Depending on the machine type and size, our price level is 30%-60% less than the European suppliers and 5-15% higher than the big local suppliers.

Q: Are you able to provide tailor-made design and production for the mixers?

A: Yes, in fact more than half of our mixers are tailor made, which is one of our strong points.

Q: Are you able to design and produce other processing equipment?

A: We are open to discuss about it.

Q: Can you provide machines to OEM customers, meaning to label their brands on the machines.

A: Yes we are doing it a lot. We have several OEM partners in the USA.

Q: Do you have agent network out of China?

A: Yes we do have agents but only in some countries, for example in USA, Germany, Poland, Spain, Denmark, Turkey, Argentina, etc. We are still looking for more agents because we believe to work with agents is the best way to do business.

Q: What is your delivery lead time of the mixing equipment.

A: Depending on the size and level of customization, but usually it is from 6-14 weeks.

Q: How do you pack and ship the mixing machines?

A: For machines don't require full container loading, we will pack them in wooden case. For FCL (full container loading) shipment, we will just wrap the machines in plastic films and fix them in the container. The shipment can be either by air or by sea